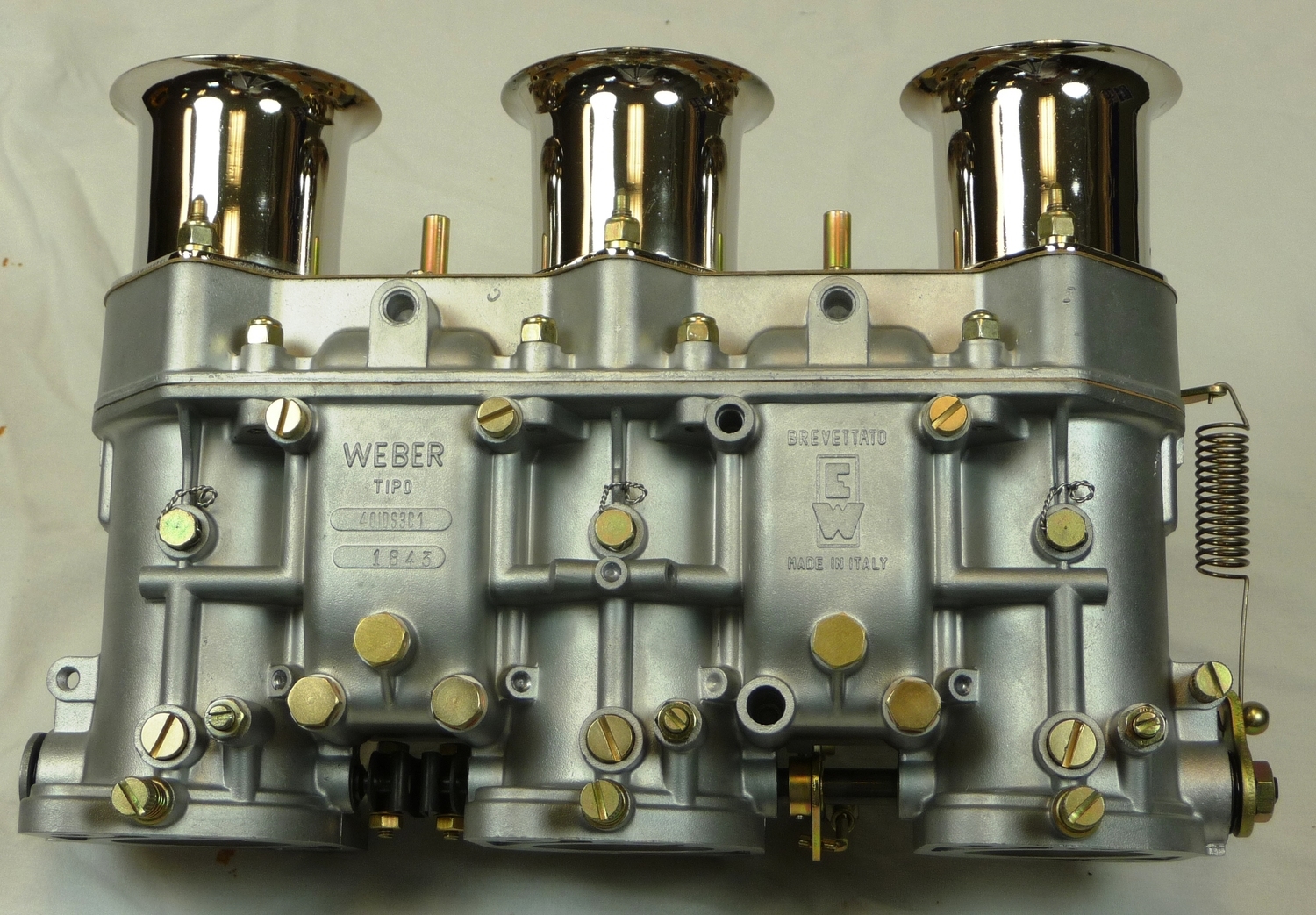

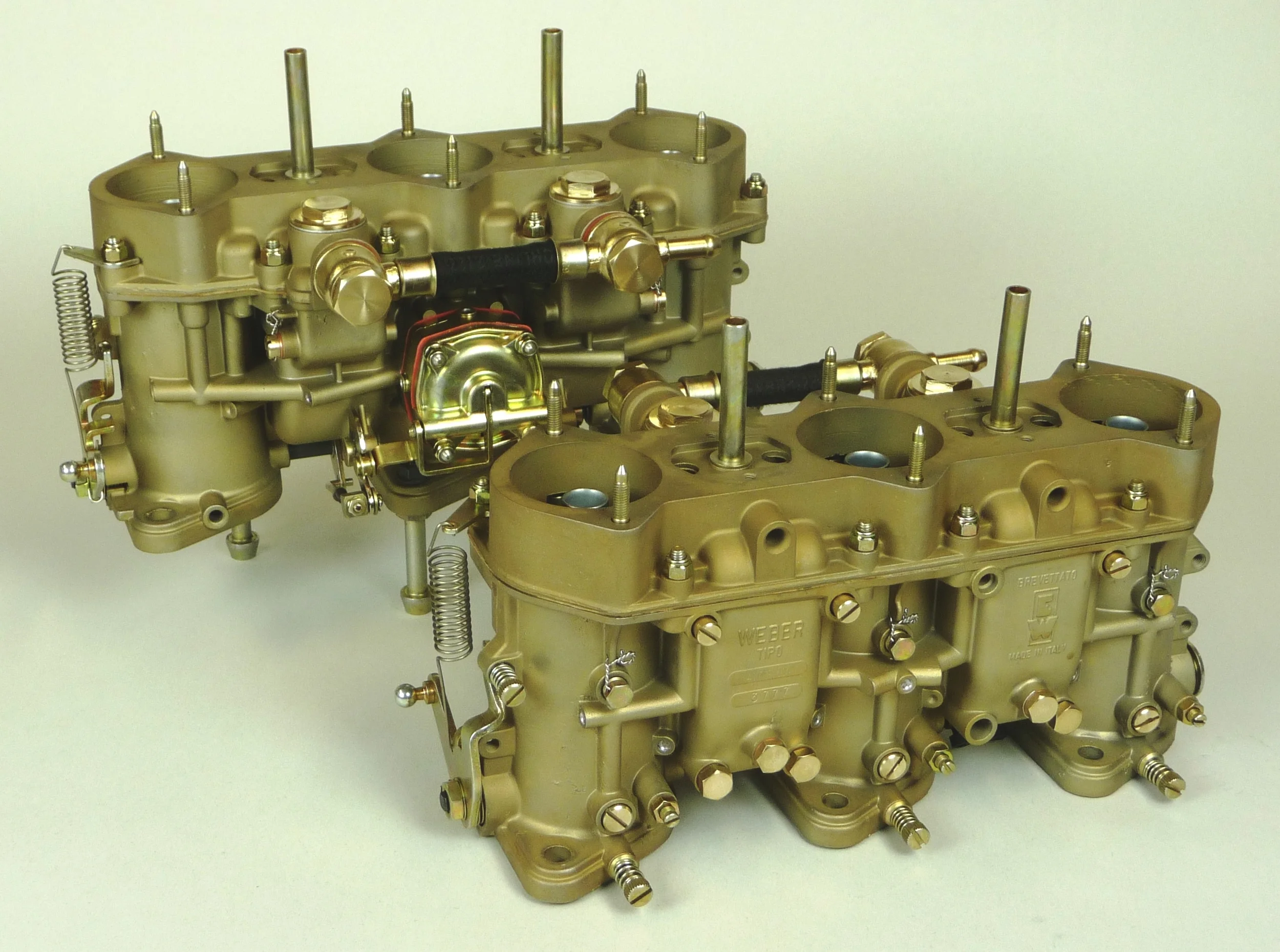

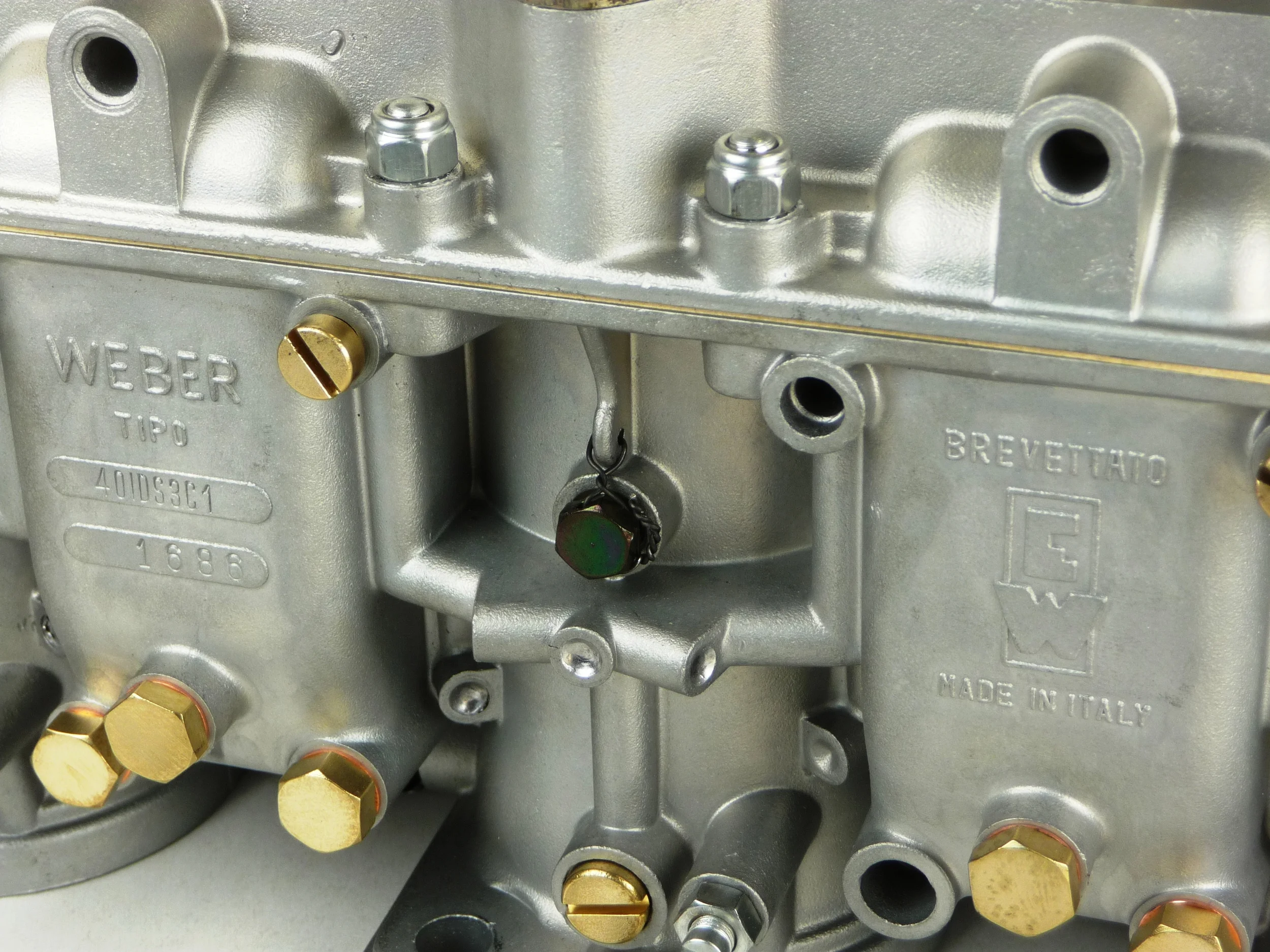

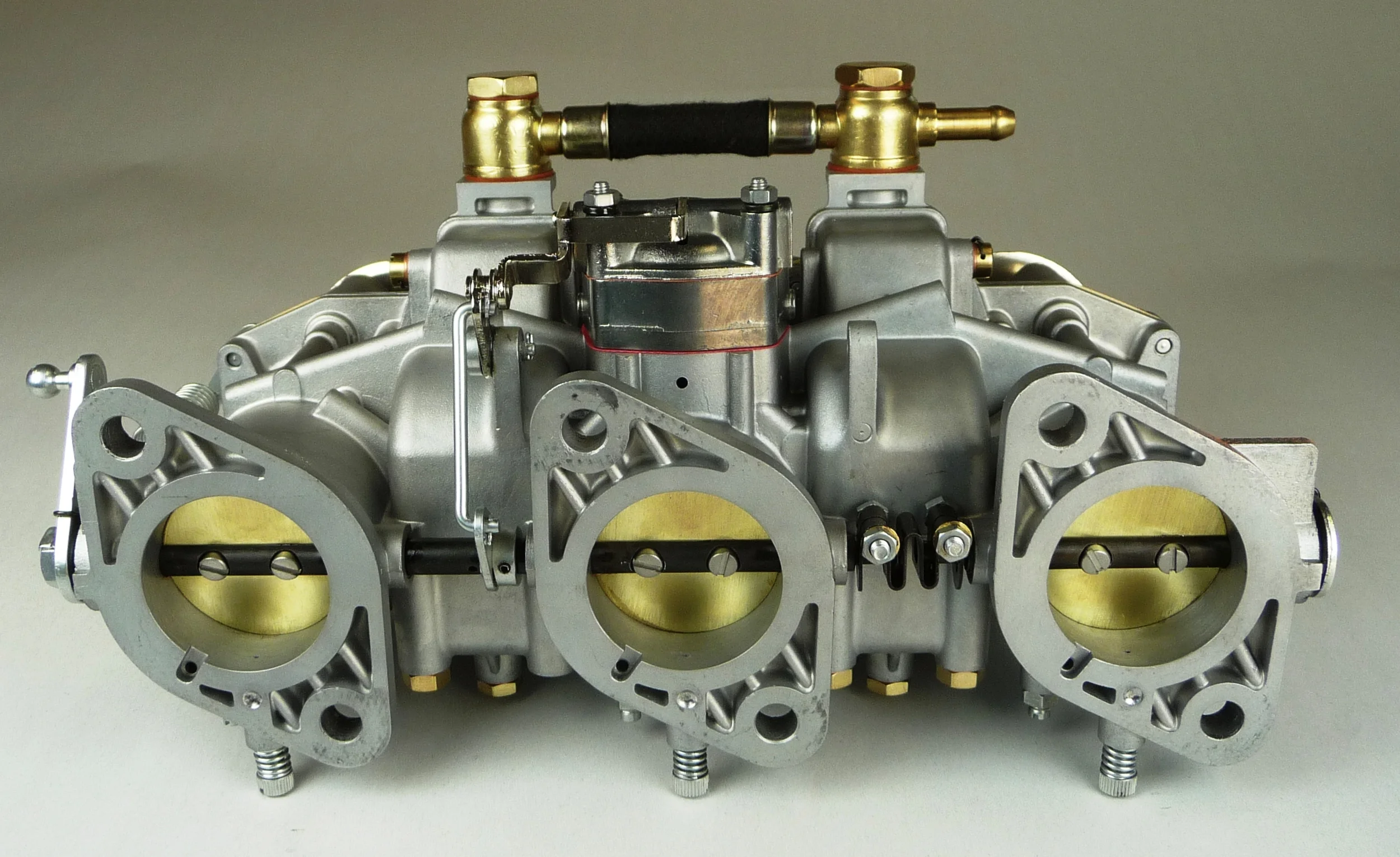

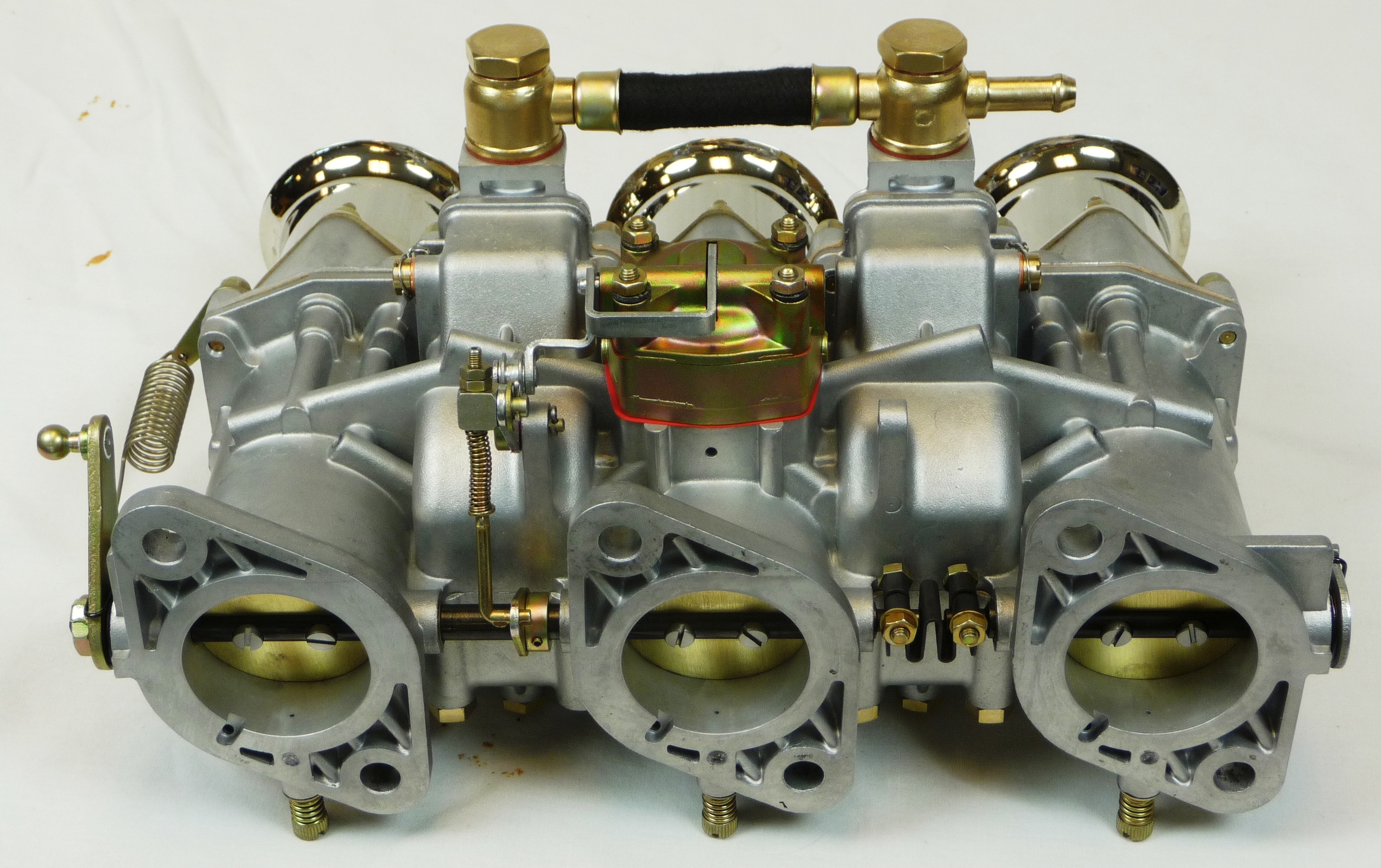

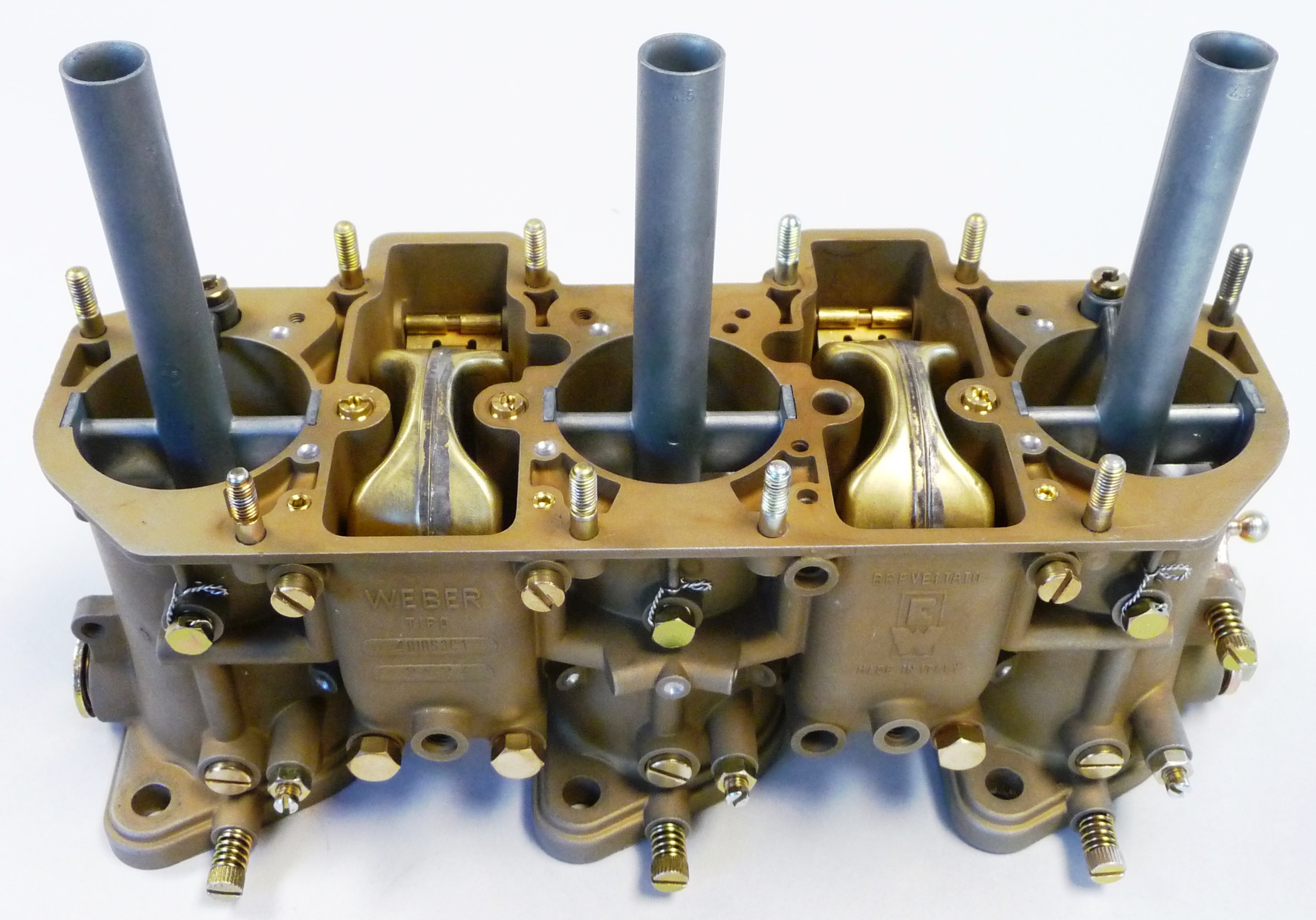

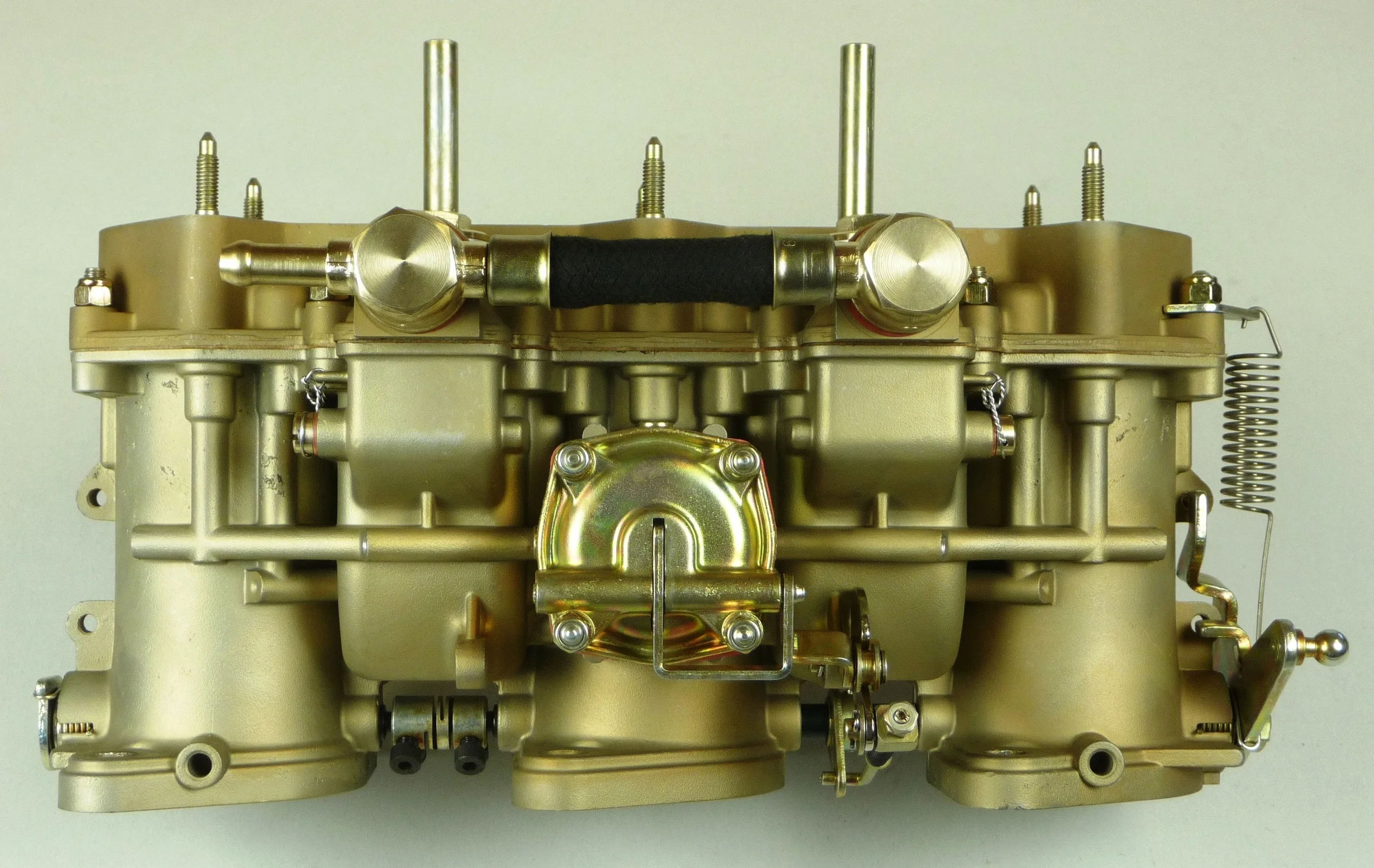

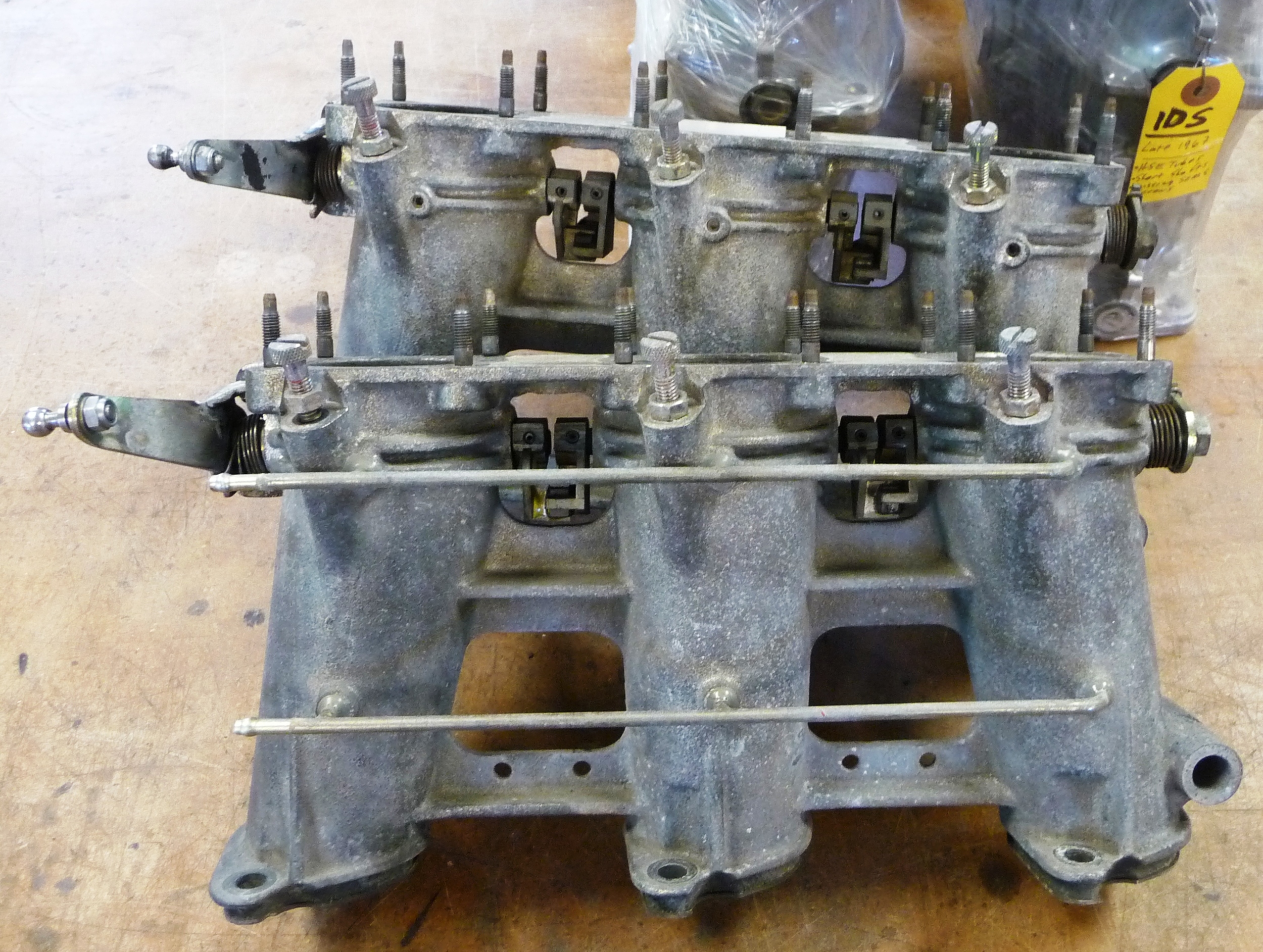

This set of Webers is very special since they were produced for the very first of the 911S engines. They were identical to the 40IDA3C Webers used on the Normal 911 engines except they were re-jetted for the higher performance 911S engines. To identify this jetting change the ends of the throttle housings were stamped with a "S" to identify the jetting differences from the Normal 40IDA3Cs. Later in production the 911S engines were suffering detonation issues at sustained, high speed operation so the 40IDS3C version of the Weber carburetors were produced. These upgraded carburetors used a secondary fuel delivery that was activated by high engine intake air-flow and supplementary fuel was delivered via "High Speed Enrichment Tubes" which are the most obvious change to the standard Weber. Upon adoption of this design revision for the 911S all subsequent throttle housings incorporated the cast-in provision for fuel galleries to feed the 40IDS3C version and its High Speed Enrichment tubes. Non-IDS throttle bodies simply did not machine the internal passageways.

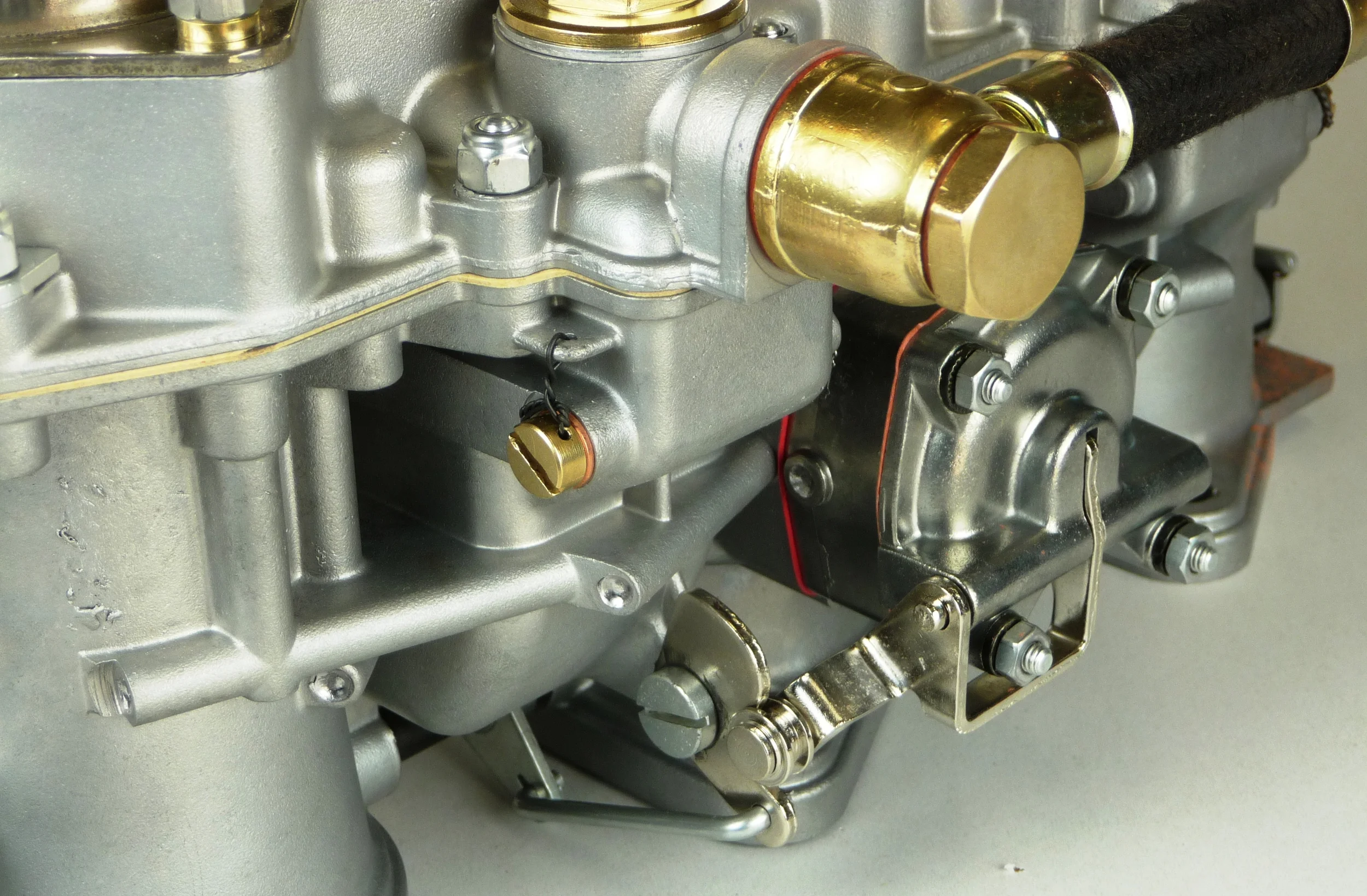

This set and other early, pre-40IDS3C throttle housings will have the same appearance in the areas around the accelerator pumps; there are external fuel galleries supplying fuel for the accelerator pump jets and no gallery provision for the High Speed Enrichment Tubes.

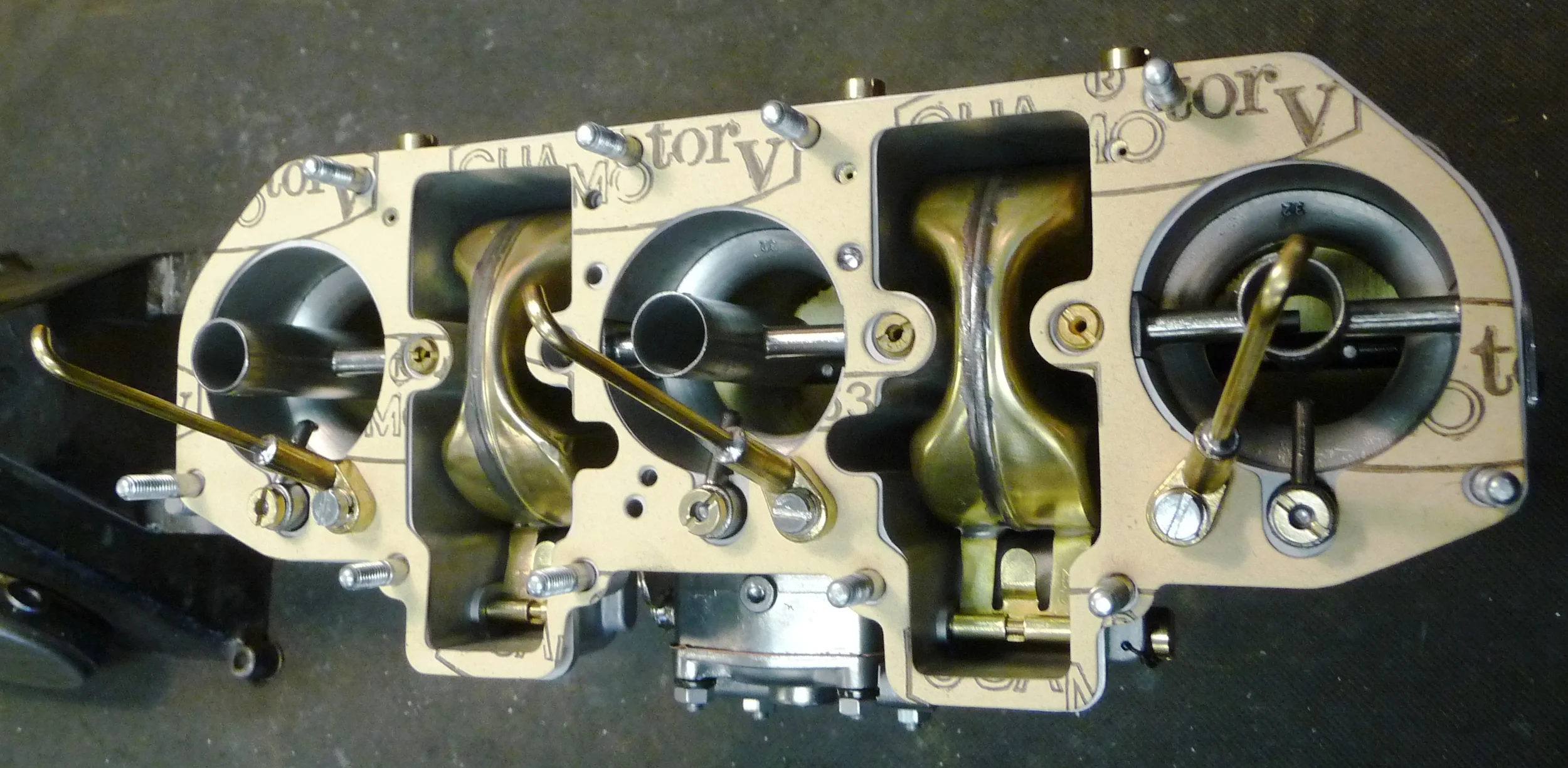

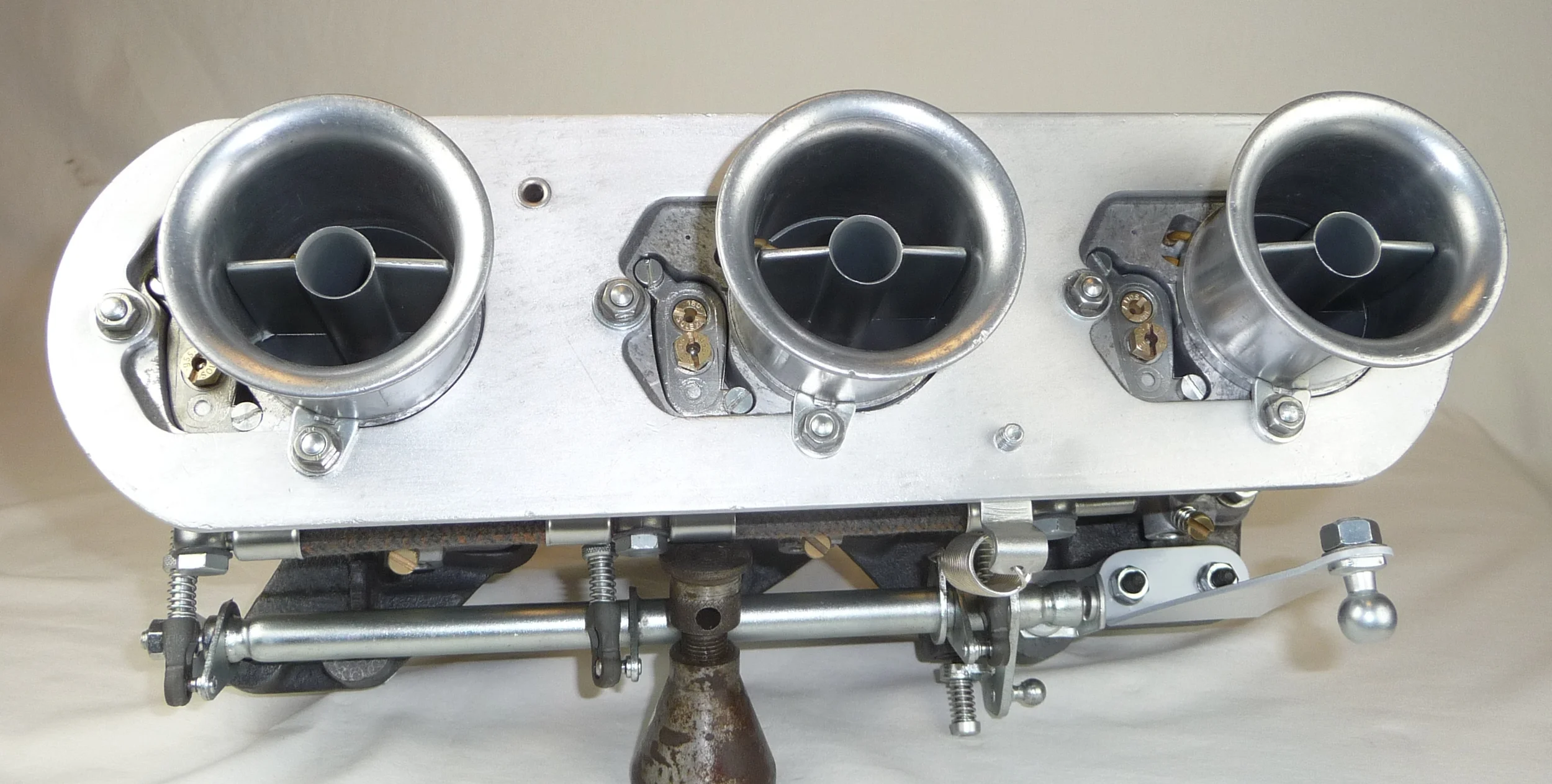

This set of early IDA(S) Webers are shown mounted to an equally scarce set of sand-cast intake manifolds which were quickly developed for use when Webers first began to replace the Solex 40PI carburetors. The Webers were already developed for use by Porsche on their 906 prototype race engines but the permanent molds for die-cast manifolds had not been created so an expedient solution for quick delivery was to use sand-cast manifolds.

Other details of the earliest 40IDA3C Webers include:

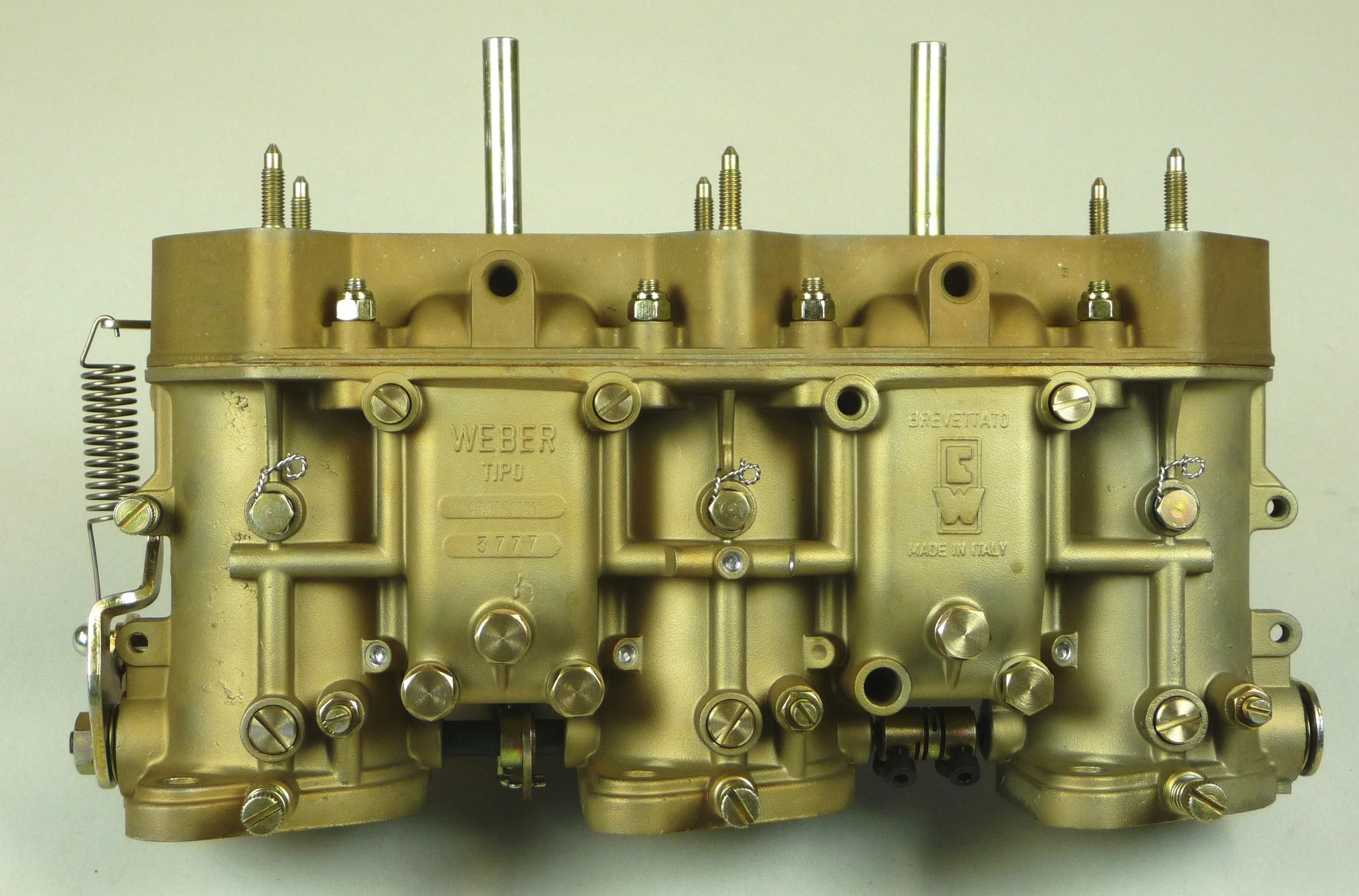

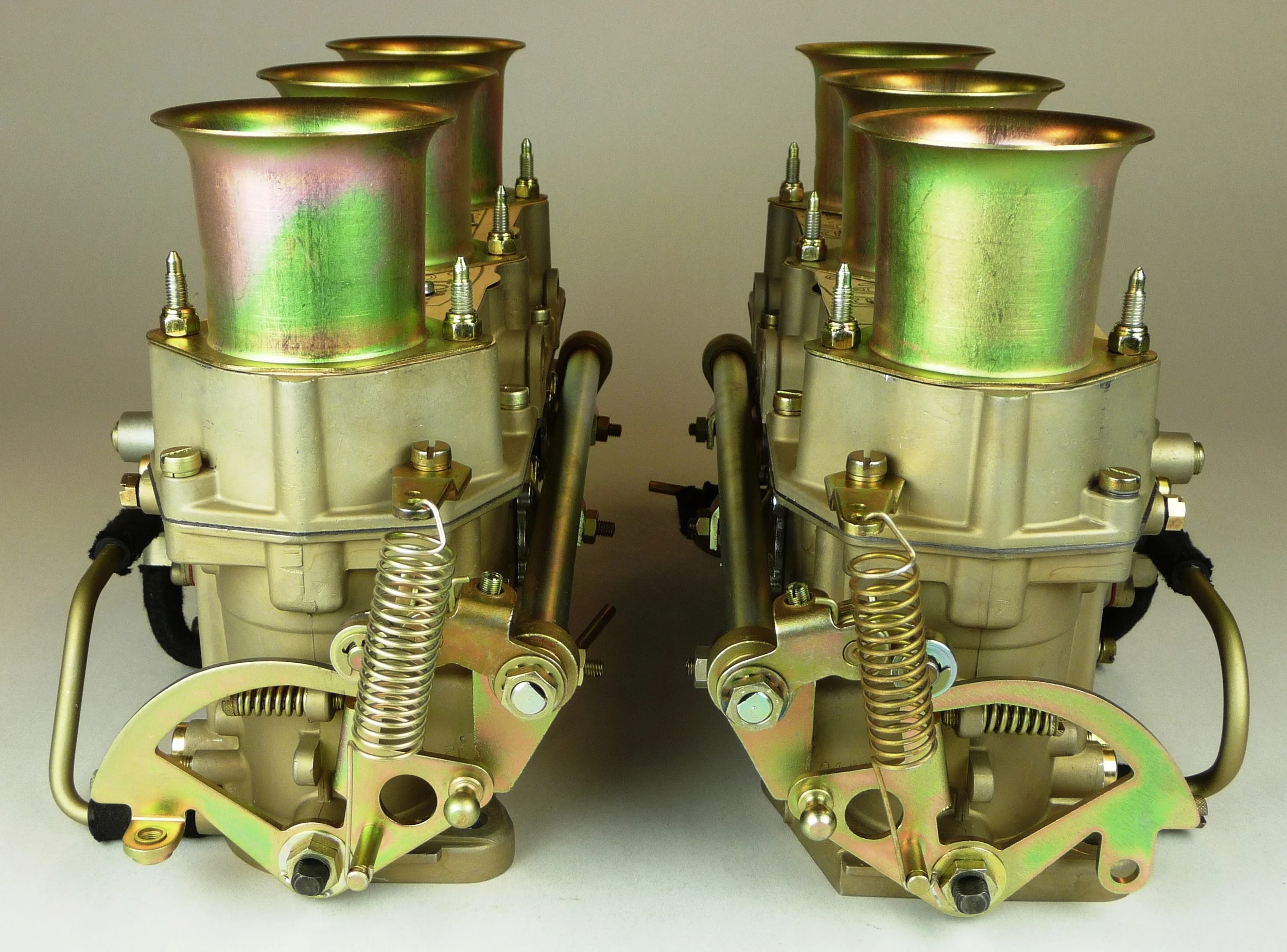

-The throttle housings and top covers for these Webers did not have any finishing operations so they have the as-cast aluminum color. Starting in 1968 these components were given a protective "Alodine" coating that is easily identified by the brown/green tint. These housings were finished with a clear Alodine finish to help preserve them from corrosion and discoloration.

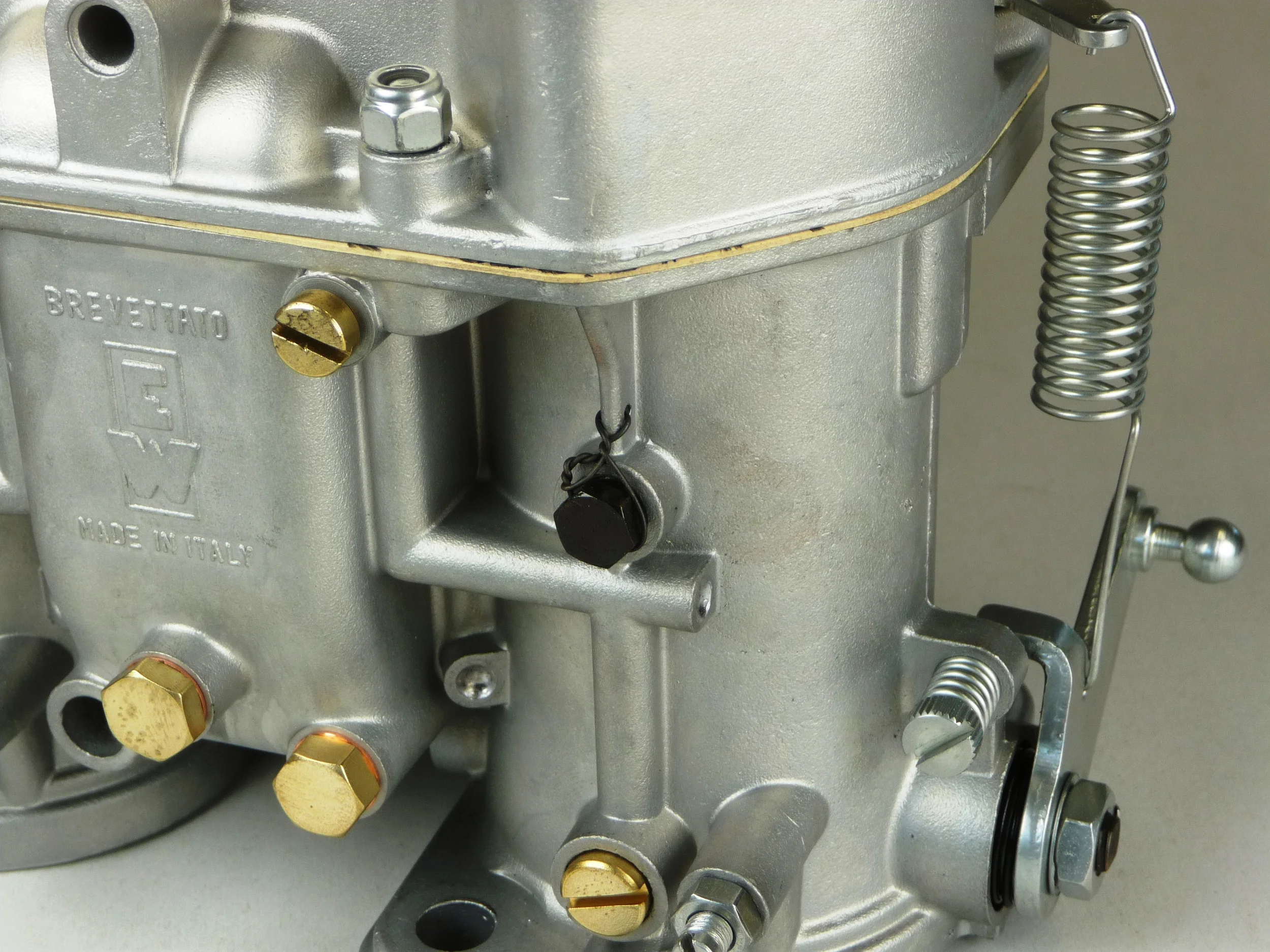

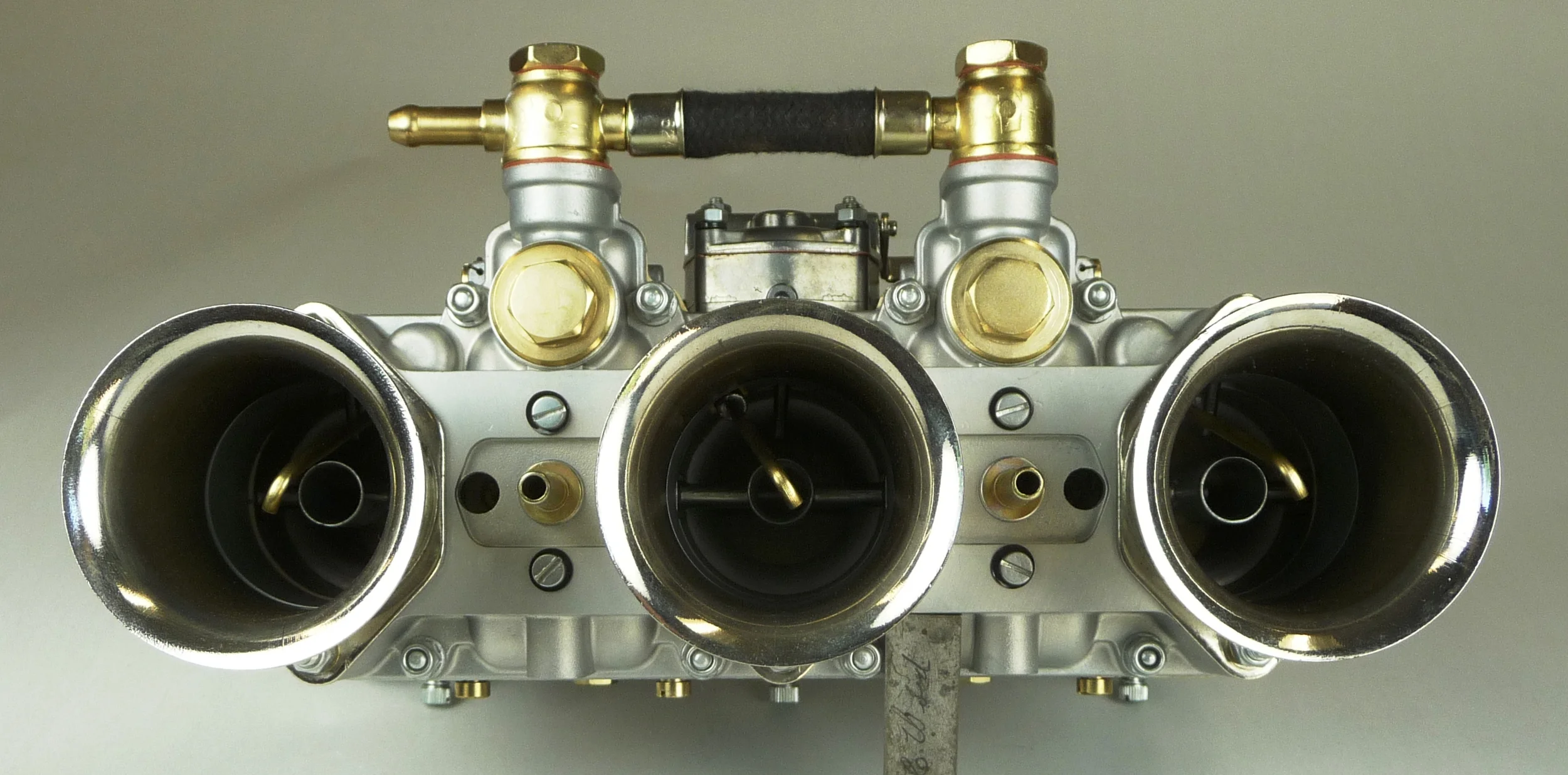

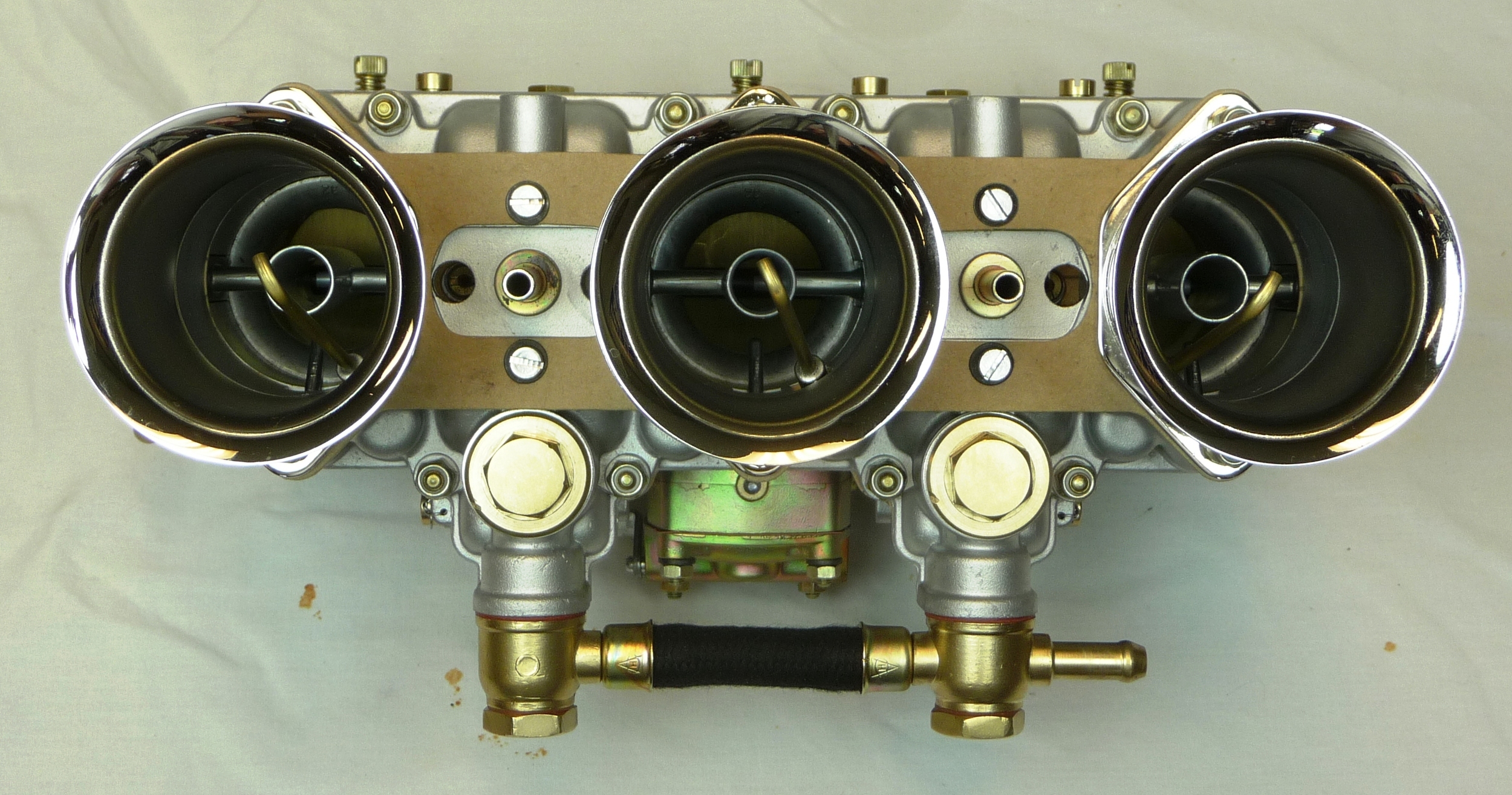

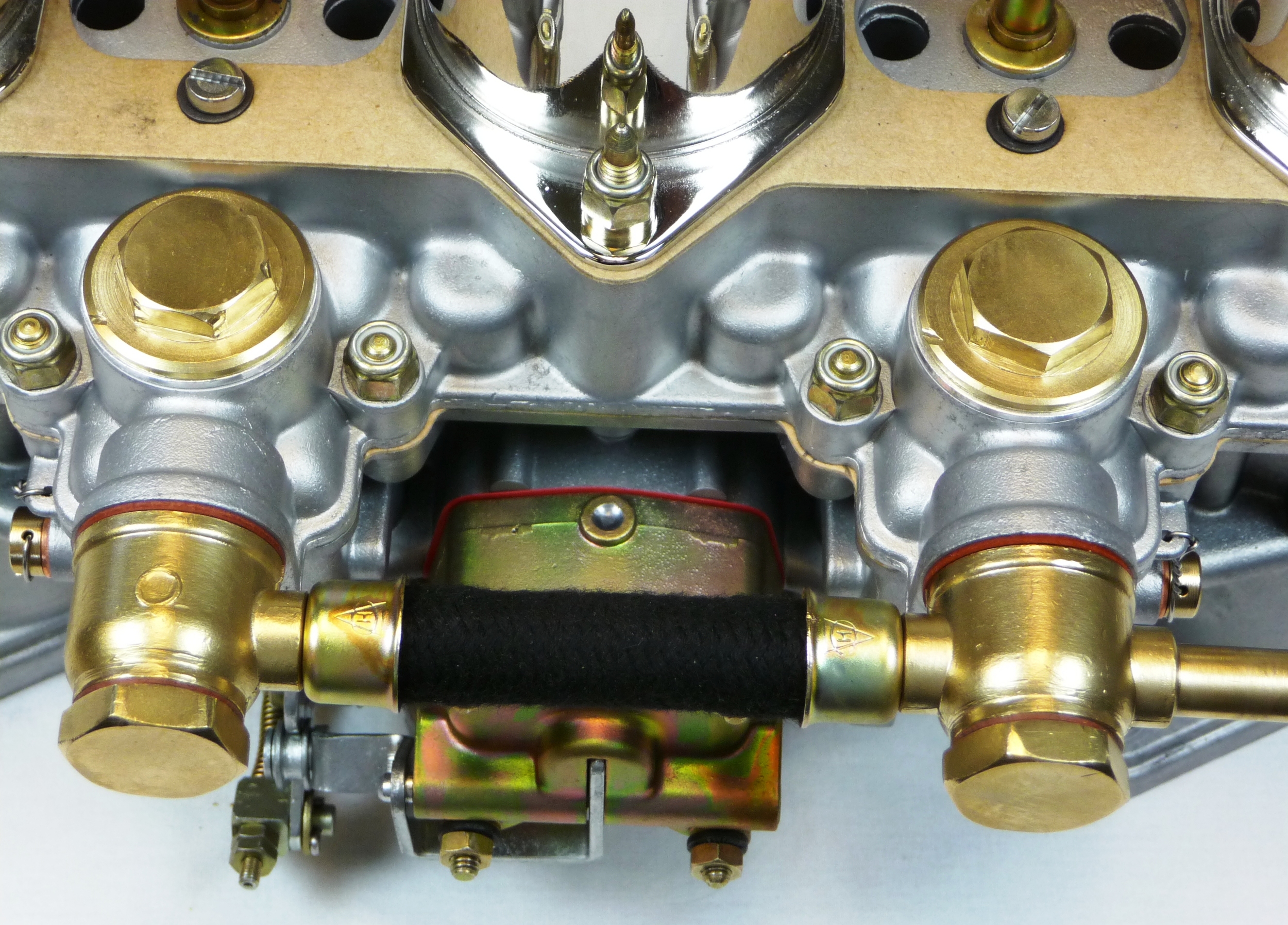

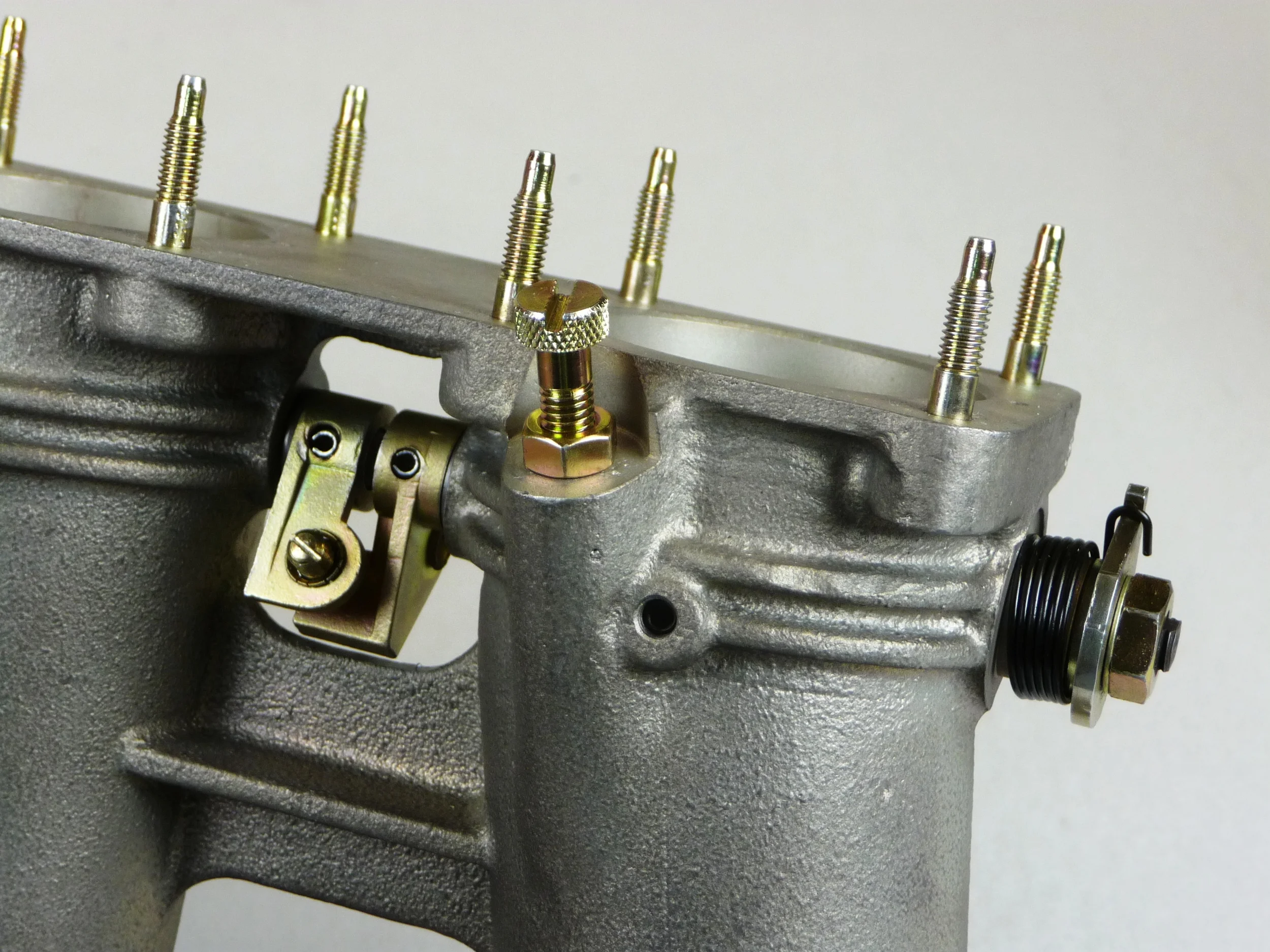

-Fuel inlet banjo fittings are of two piece construction with a cast body and the nipples are installed by soldering. It is most probable that the cost of manufacturing was decreased by making them a one piece casting which is why the next generation design has a shorter collar between the nipple and the main body, there is no need for a longer collar for the solder connection of the earlier version.

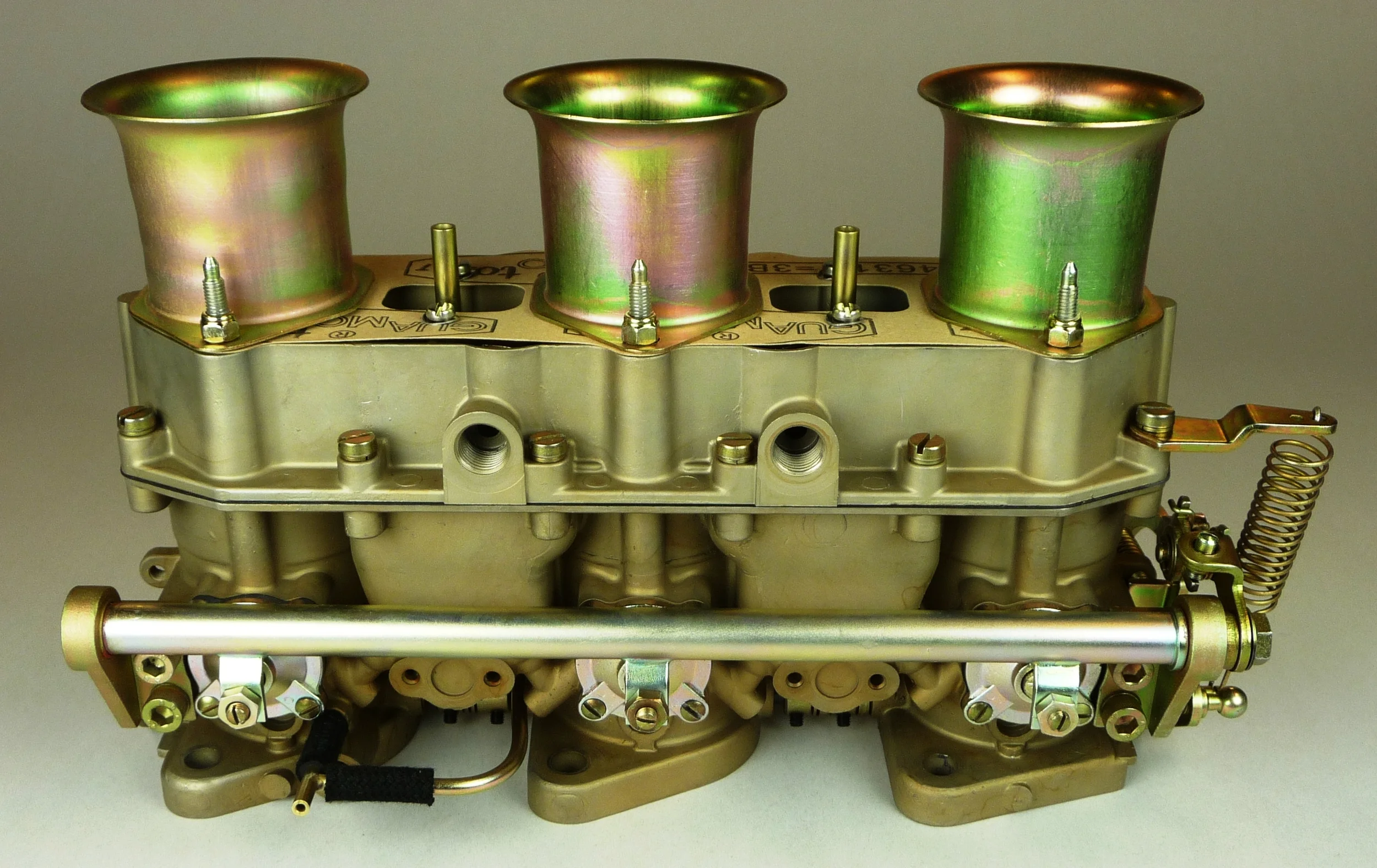

-Black safety wire of correct gauge installed per OEM tying method

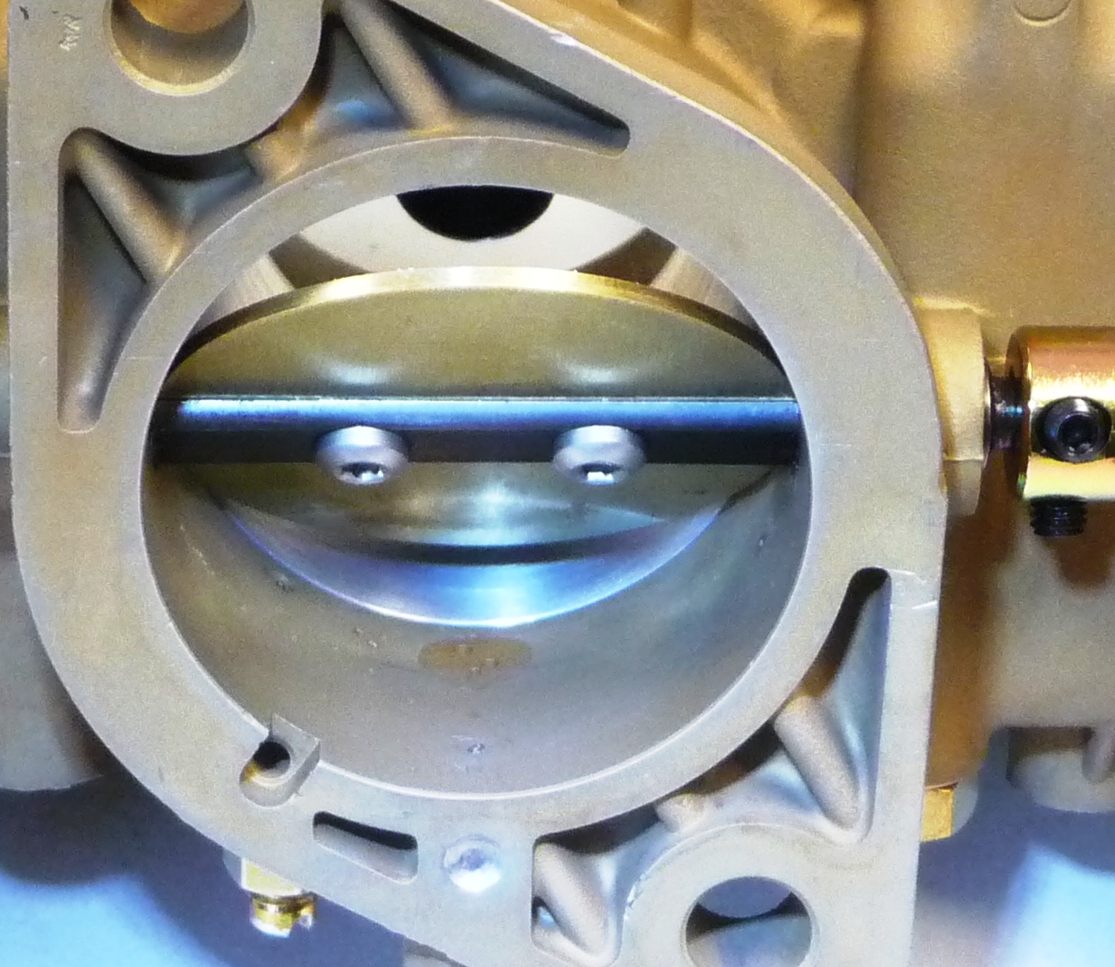

-Black grub screws retaining the main venturis

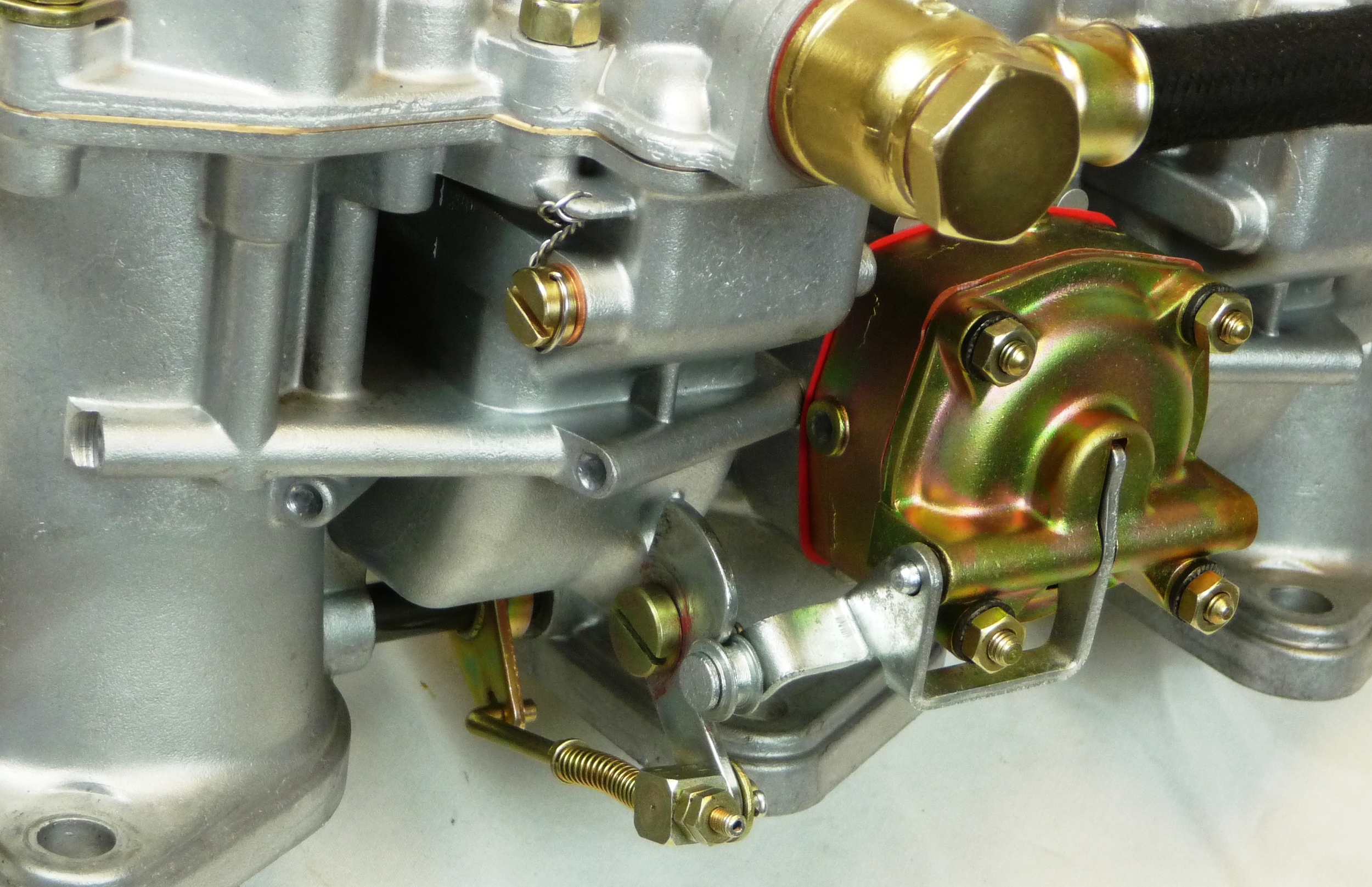

-Shaft couplings are "folded-spring" of the earliest version. There were two versions of the folded-spring coupling before the cylindrical shaft coupling was adopted; the earlier version incorporated notches used to keep the heads of the clamping bolts from twisting during tightening of the nuts but these notches were stress risers and in a spring steel component, any stress riser is a poor design which leads to breakage.

-Black throttle return springs (the throttle-shaft, concentric springs at each end of the throttle body)

-Tall Weber original nylock hex nuts used for M5 studs, these are NLA. I have collected good, used nuts over the years and refinished them for installation on this project

-The split lock washers used for locking the hex nuts on the accelerator pump covers are OEM, heavy cross-section and have the serrations on the faces in contact with the nut and the top cover of the pump (hard to find these also, very specific to early Weber carbs and NLA)

-The accelerator pump rods are NLA and OEM; I have been able to acquire a few in excellent, used condition over the years so I could use them on special projects like this one

-The top covers of the throttle bodies are correct to the main bodies; top cover casting design changed forever as did the main body castings upon introduction of the IDS throttle bodies in mid 1966

-Accelerator bodies and top covers are left as "as-cast" zinc finish but internal chambers are modified for venting per later versions

-Accelerator pump covers are early style without stiffening rib around their perimeter edges

-All studs are of the earlier version with machine-cut threads and radiused ends; later studs had roll-formed threads and sheared ends

-Main venturis, squirter nozzles, squirter nozzle bolts, main jet carriers, fuel bowl drain bolts, idle jet carriers, banjo fittings, banjo bolts, idle air screws, mixture screws and progression port plugs are period correct and OEM. Again, I collected good condition, OEM parts in anticipation for use on a deserving project like this.

-Nickel plating used on:

-Lever arm and fulcrum pin installed into the top covers of the accelerator pumps

-Cam lever that is mounted on the float bowl that operates the lever arm in the top cover of the accelerator pump

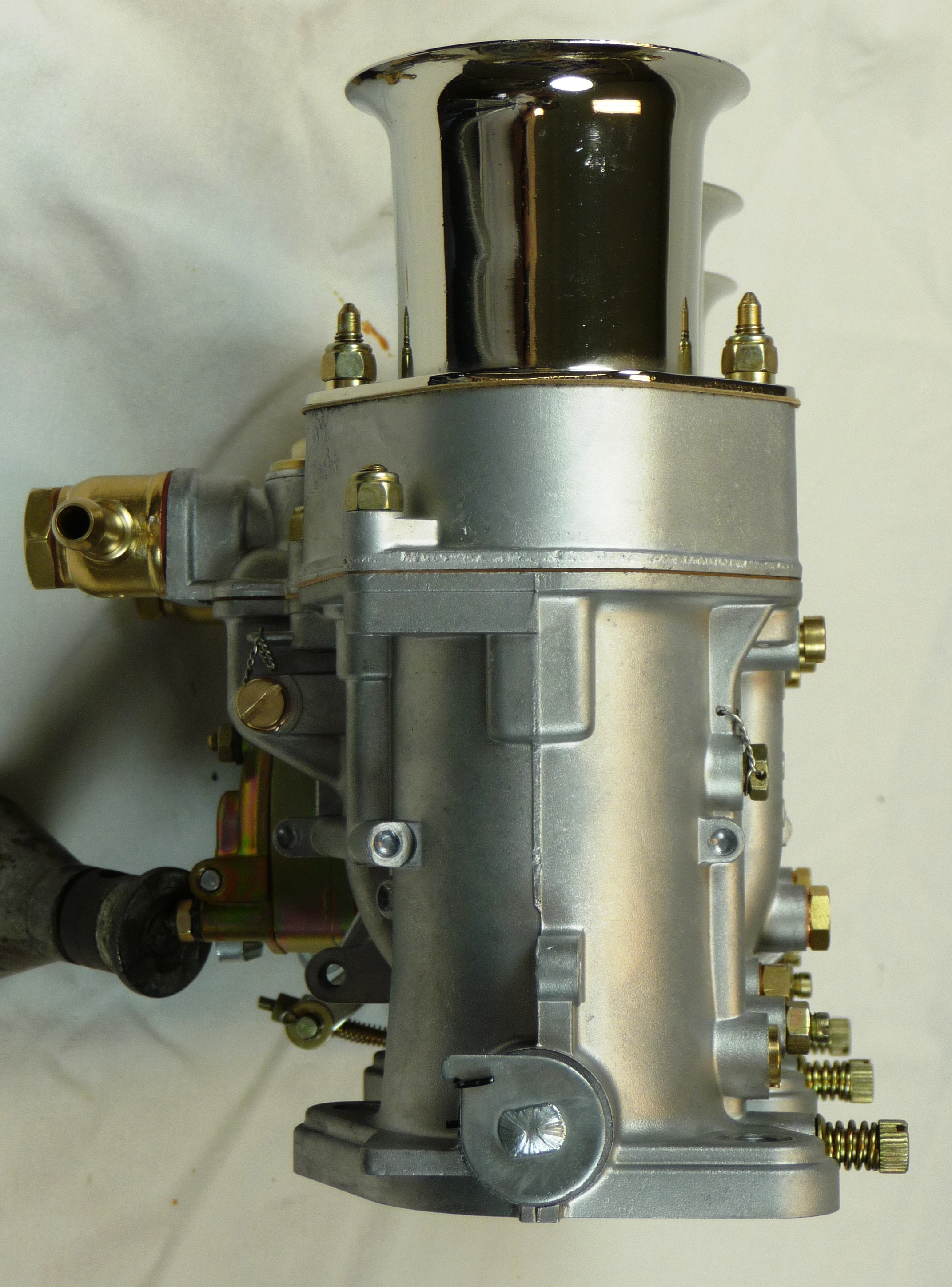

-Intake air horns

-Air horns are period correct with thick flanges and spun, not brazed construction

-Brass spacer washers installed between nylock nuts and flanges of air horns; these are not shown on any Weber drawing but were installed as by Porsche

-M4 cheese head screws used for installation of air cleaner are OEM original screws, new screws do not have the same head profiles as original ones have

-The fuel line ferrules are not OEM, unfortunately,OEM Cohline ferrules were not available to use for this project so I created replicas and zinc plated them with a yellow chromate finish as was original

-All hardware and studs are zinc plated with silver finish as was OEM except for black, yellow and nickel finishes as mentioned above. Cadmium finishes were not used on Weber carburetors and this has been documented rather carefully.